Gateros Plating

Chrome Plating Solution 250 mls

Chrome Plating Solution 250 mls

Couldn't load pickup availability

Brand: Gateros Plating

Unit Type: 100ml

Manufacturer Part Number: Does Not Apply

Country/Region of Manufacture: United Kingdom

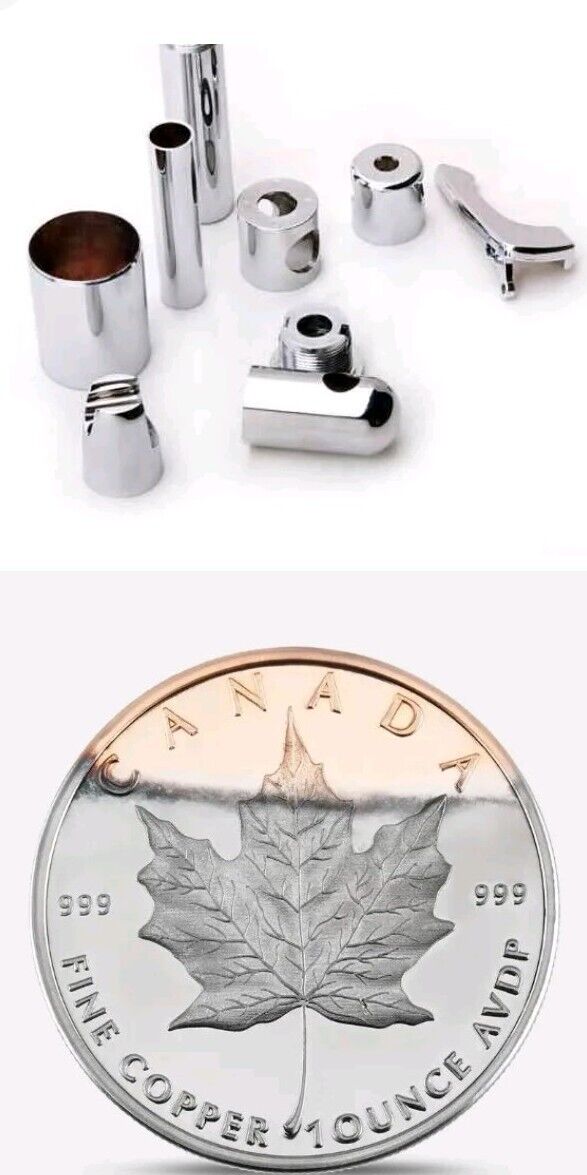

Chrome Plating Solution 250 ml.

Chrome Electrolyte 250 ml - Chrome Plating Solution

high-performance electrolyte for galvanic chromium plating

bright deposition

works already at room temperature

wide current density range

suitable for bath electroplating and pin electroplating

Please note this is just the solution, you will need the anodes ,ideally aluminium

Description

High-quality chrome electrolyte for self-chrome plating

Chrome coatings not only protect against oxidation and corrosion, but also give workpieces an attractive appearance. Our electrolyte is based on chromium(III). While the industry originally mostly used chromium(VI), nowadays chromium(III) compounds are mostly used for chrome plating, as this process poses a much lower risk to humans and nature. This electrolyte contains all our know-how - we were able to make it much brighter and more powerful. Current densities of up to 20A/dm² can be achieved. Usually, chromium is deposited in the layer system copper-nickel-chromium, whereby the nickel intermediate layer additionally protects against corrosion.

The advantages:

uncomplicated electroplating process for applying a chromium layer

chrome layer is very similar in colour to the results of hexavalent chromium baths

can be used for all common processes such as bath electroplating and pin electroplating/tampon electroplating

impresses through high adhesion and abrasion resistance

works at room temperature (temperature range 15 to 50 °C)

has a high hardness of up to 1200 HV

good reflection and gloss

higher permissible metal impurities than comparable processes, thus easier to use

In order to achieve a perfect result with the chrome electrolyte, the appropriate anodes are required for the galvanic process used. Anodes made of aluminium, platinised titanium, platinum or iridium are recommended.

Aluminium anodes have proven to be particularly advantageous, they are especially cost-effective and the electrolyte retains its excellent colour.

Share